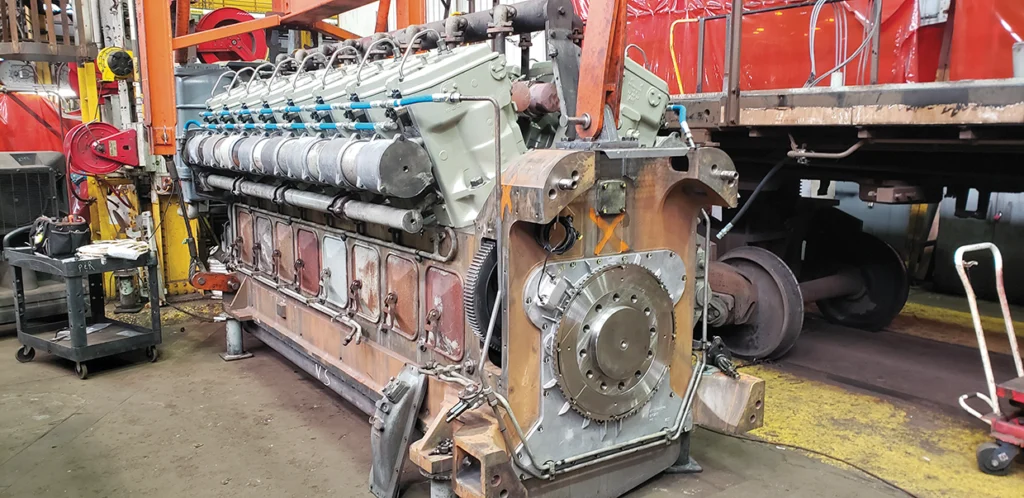

Members of Altoona, Pa., Local 2273 have helped strip hundreds of Norfolk Southern locomotives like this one (top) down to the wheels (above left) and then rebuild them to house new AC-powered traction motors (above right).

Thanks to the work of IBEW electricians with Altoona, Pa., Local 2273 and a spirit of solidarity with other trades, 1,000 upgraded Norfolk Southern locomotives are in service throughout the eastern half of the U.S.

For nearly 10 years, 12 daylight-shift and 10 second-shift Railroad Branch electricians at Norfolk Southern’s Juniata have been stripping direct-current power units from the railroad’s 4000-series locomotives — many of which are decades old — and replacing them with modernized units driven by alternating current.

“Speed is a lot more controlled with an AC-powered traction motor,” explained Local 2273 Chair Kevin Beers, “and the adhesion is more stable with it on the tracks.”

– Altoona, Pa., Local 2273 President Kevin Beers

“We’ll strip them the whole way up through the shop and then rebuild them as they’re coming back down.”

Because of a series of technological improvements in recent years, “these AC locomotives now are unbelievable with their power and traction,” said Railroad System Council 6 Chair Shannon Spotswood, whose jurisdiction includes Local 2273.

“We used to have a whole spectrum of stuff that we had to be able to troubleshoot and work on,” said Spotswood, a 25-year IBEW member who worked in a Roanoke, Va., Local 813-represented Norfolk Southern shop and later served for 15 years as the local’s chair. “The AC stuff didn’t really start coming on strong at Norfolk Southern until probably 15 years ago, and now they’re dominating.”

The IBEW’s work at Juniata supplements locomotive upgrades also taking place at a Wabtec facility in Erie, Pa., whose workers are represented by another union.

“We do like 20 a year here,” Beers said. “Overall, it’s been a pretty well-thought-out joint effort with Wabtec and Norfolk Southern.”

Local 2273 Vice President Chris Snyder noted that Railroad Branch workers at Norfolk Southern’s facility in Roanoke, Va., helped convert 47 locomotives to AC power before that plant’s closure in 2020.

“With next year’s projected 20, we’ll have done here, in-house, 239 locomotives,” Snyder said.

At Juniata, the roughly nine-week locomotive upgrade process works assembly-line-style. “We’ll strip them the whole way up through the shop and then rebuild them as they’re coming back down,” Beers said.

It takes about two weeks to dismantle locomotives’ DC systems, followed by four to five weeks of rebuilding.

“It’s nothing different from what we’re used to in this shop already,” said Beers, whose local represents more than 130 Norfolk Southern workers who service and maintain hundreds of locomotives every year. “We can do just about anything here.”

And they do it well, Spotswood said. “I’ve been up there several times in the past few years, and I know those folks there have a diverse set of skills,” he said. “What’s really phenomenal is they have the ability to lift a whole locomotive in the air. It just blows your mind at what they’re able to accomplish.”

Once the main upgrade work is complete, the locomotives undergo a week of load and diagnostics testing on an outdoor track at Juniata’s yard before receiving a fresh coat of paint.

“One benefit for them is they’re getting a new cab and an upgraded management system,” Snyder said. “They’re stating that the fuel efficiency is 25% better, it’s a 40% greater reliability for the locomotive itself and a 55% better hauling capacity.”

Beers said the whole process — a team effort by all the crafts involved — has been running smoothly.

“There’s a larger sense of brotherhood [at Juniata],” Spotswood noted. “We’re all union brothers and sisters, so we all have the same objective.”

That’s crucial when it comes to working safely, he said.

“If we don’t work together in a seamless fashion, somebody’s going to get hurt,” Spotswood said. “With the amount of weight of some of these objects, people can lose fingers, hands or even lives.”

The outlook on the 4000-series locomotive work appears steady, Beers said, with upgrades to Norfolk Southern’s Evolution series locomotive now being looked at, as well. It’s a measure of good news for Local 2273, which is among many in recent years whose ranks have been gutted by most railroads’ adoption of “precision scheduled railroading,” a radical, penny-pinching efficiency strategy that has resulted in the elimination of hundreds of IBEW and other union workers’ jobs.

“At Juniata, they take great pride in being the best at what they do,” said Spotswood, who was System Council 6’s vice chair before he became chair in July.

Aside from the improved emissions and longer locomotive lifespans that come with the upgrades, “it’s just so impressive to see a locomotive come in that’s 20 to 30 years old be stripped down to the frame and then watch it all come back together,” Snyder said.